China Injection Molding Procurement: Key Steps

The important meeting has recently finished, your new product is a go, the timeline is aggressive, and the budget is, let’s say, constrained.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

You nod, of course. It seems sensible at first glance. Savings can be substantial. Yet your thoughts are already spinning. You’ve heard all the horror stories, right? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

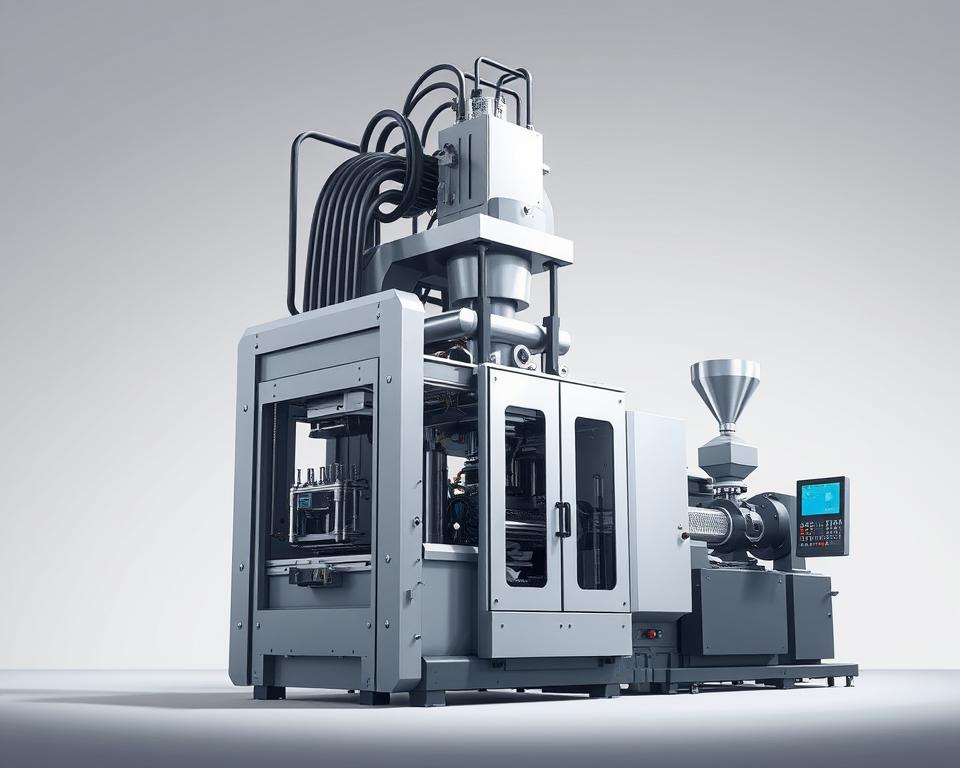

Here’s the thing, though. Sourcing China injection molding doesn’t have to be a gamble. It’s a project, just like any other. And its outcome hinges on the approach you take. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Forget the horror stories. Let’s walk through a real-world playbook for getting it right.

Initial Step: Prepare Your Information

Before you mention “supplier” or browse Alibaba, organize your internal data. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. Don’t assume a remote factory can guess your needs. It’s akin to asking someone to price-build “a structure” with no details. The replies will range from absurdly low to exorbitant, none of which help.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. It’s the cornerstone of your entire effort.

What should you include?

Begin with 3D CAD models. These are non-negotiable. Use standard formats such as STEP or IGS to ensure compatibility. This is the authoritative CAD geometry.

But 3D isn’t enough. Include precise 2D engineering drawings. This is where you call out the stuff that a 3D model can’t communicate. Think tolerances, material grades, finish specs, and any feature-critical notes. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Next up, material. Avoid generic terms like “Plastic.” Even “ABS” alone is too vague. Be explicit. Call out SABIC Cycolac MG38 (black), for example. Why? Because resin grades number in the thousands. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Don’t forget the commercial info. What is your Estimated Annual Usage (EAU)? You must specify if it’s a 1K-part tool or a 1M-part production run. Cavity count, tooling cost, and per-unit pricing depend on volume.

The Great Supplier Hunt

Okay, your RFQ package is a work of art. who will you target? The web is vast but overwhelming. It’s easy to find a supplier; it’s hard to find a good one.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They offer breadth but not depth. Treat them as initial research tools, not final solutions. Narrow your pool to about a dozen promising firms.

But don’t stop there. Consider using a sourcing agent. They do cost extra. Yet top agents deliver reliable, audited suppliers. They bridge language and cultural gaps. As a newcomer, this offers priceless security. It’s schedule protection.

Also consider trade fairs. With budget permitting, Chinaplas or similar shows are invaluable. Nothing beats a face-to-face conversation. Inspect prototypes, interview engineers, and sense their capabilities. Plus, ask peers for referrals. Ask other project managers in your network. A recommendation from a trusted peer is often worth its weight in gold.

Sorting the Contenders from the Pretenders

With your RFQ dispatched to dozens of firms, bids begin to arrive. Some prices will undercut logic, others will shock you. Now, sift through and shortlist 2–3 reliable candidates.

How to proceed? It’s a bit of an art and a science.

Begin with responsiveness. Are their replies prompt and clear? Can they handle detailed English exchanges? The true litmus: are they raising smart queries? Top vendors will critique and inquire. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” Consider that a big green light. It shows they’re engaged and experienced. A “Sure, no issues” vendor often means trouble.

Afterward, verify their technical arsenal. Get their tooling inventory. Review examples of parts akin to your design. Don’t pick a micro-molding shop for large components.

Finally, inspect the factory. You can’t skip this. Just as you interview hires, audit suppliers. You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They’ll send a local inspector to the factory for a day. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. It’s the best few hundred dollars you will ever spend on your project.

Transforming CAD into Real Parts

After picking your vendor, you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the real fun begins.

Initially, expect a DFM report. DFM means Design for Manufacturability. It’s the engineering critique for moldability. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. Comprehensive DFM equals a top-tier supplier. It’s a collaboration. You work with their engineers to refine the design for optimal production.

With DFM sign-off, toolmaking begins. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These represent the first trial parts. It’s your first real test.

Expect T1s to need tweaks. That’s standard process. Look for small flaws, slight size errors, or surface marks. You critique, they refine, and T2 plastic mold in China parts arrive. This process might take a couple of rounds. Build buffer time for sample iterations.

Finally, a flawless part arrives. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is now the benchmark sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Final Steps to Mass Production

Landing the golden sample is huge, yet the project continues. Next up: mass manufacturing. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. This often involves a pre-shipment inspection. Again, you can hire a third-party service. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. They provide a photo-filled inspection report. After your approval, you release the shipment and final funds. This simple step prevents you from receiving a container full of scrap metal.

Don’t forget shipping details. Clarify your Incoterms. Are you on FOB terms, where they load and you take over? Or EXW, shifting all transport to you? These details have a big impact on your final landed cost.

Overseas sourcing is a marathon. It hinges on strong supplier relations. See them as collaborators, not vendors. Clear communication, mutual respect, and a solid process are your keys to success. Certainly, it’s complex. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re ready.